Réamhrá: Bunús Tee Foirfe Is stáplacha wardrobe domhanda é an t-léine humble, ach ní cruthaítear gach tees comhionann. Tá an difríocht mhór idir meán-léine agus léine a mhothaíonn cosúil le dara...

Léigh tuilleadhsaincheaptha Fabraicí olann síoda

Comhcheanglaíonn fabraic olann síoda, samhail de theicstílí ardleibhéil, na buntáistí a bhaineann le síoda agus olann trí theicneolaíocht chumaiscthe fíorálainn. Tá cáil ar shíoda mar gheall ar a bhogúlacht, a breathability, agus a n-airíonna ionsú taise agus a rialáil, ag tabhairt uigeacht íogair agus réidh don fhabraic; Soláthraíonn olann, lena coinneáil agus a leaisteachas maith, teas, compord, agus friotaíocht mhaith roic. Mothaíonn an creatlach silky agus bog, tá dath te agus lustrous air, agus taispeánann sé uigeacht neamhghnách ard-deireadh. Déileáiltear go speisialta go speisialta le hinfhaighteacht, a fheidhm allais allais, a fhriotaíocht a chaitheamh, agus leis na hairíonna frith-philleáilte chun a chinntiú go bhfanann an fhabraic tirim, compordach, agus buan i dtimpeallachtaí atá ag athrú. Tá fabraic olann síoda oiriúnach chun cultacha, cótaí, geansaithe, agus éadaí ardleibhéil agus teicstílí baile a dhéanamh. Is rogha iontach é dóibh siúd a shaothraíonn treochtaí saoil agus faisin ardchaighdeáin. Ní hamháin go léiríonn sé blas neamhghnách an duine féin ach léiríonn sé freisin an tóir gan staonadh ar cháilíocht na beatha agus ar threochtaí faisin. Is fabraic ardcháilíochta í le feidhmiúlacht agus aeistéitic araon sa réimse teicstíle. $ $

-

Fabraic síoda olann bog geansaí atá cairdiúil don chraiceann

-

Fabraic Olann Síoda Jacquard-Frith-Chúbtha ag Caitheamh Caitheamh

-

Fabraic olann shíoda ponte compordach compordach cairdiúil don chomhshaol

-

Laghdaigh cruthúnas roic-fhrithsheasmhach in aghaidh roic dúbailte Jacquard Síoda Fabraic Te Fabraic Te

-

Teas-cruthúnas cruthúnas dúbailte fabraic olann síoda Jacquard

-

-

Mar innealtóireacht teicstíle agus éadaí soláthraí réitigh, speisialtóireacht ár gcuideachta i bhfoinsiú, a mheas, agus a sholáthar ábhair fabraice chun cinn do mhonaróirí éadaigh, brandaí, agus fo...

Léigh tuilleadh -

1. Cén fáth go bhfuil Cumasc Cotton Silk ar an Rogha Cliste le haghaidh Léinte Saincheaptha Ard-Deireadh? Is minic a bhíonn aincheist clasaiceach mar thoradh ar shaothrú na fabraice léine foirfe...

Léigh tuilleadh -

Iniúchadh a dhéanamh ar na Buntáistí a bhaineann le Fabraic Cniotála Jacquard Mercerized le haghaidh Craiceann Íogaire Is minic a bhíonn deacrachtaí ag daoine aonair a bhfuil craiceann íogair or...

Léigh tuilleadh -

Díphacáil Sármhaitheas Snáithín Cadáis Supima An Buntáiste Stáplacha Breise-Fada: Marthanacht agus Bog Tá bunús na teicstíle eisceachtúil seo in úsáid a bhaint as cadás Supima, éagsúlach...

Léigh tuilleadh

What post-processing processes are performed after the silk wool fabric is dyed? For example, washing, ironing and finishing. What impact do these processes have on the final texture of the fabric?

The washing process is the first important treatment link after silk and wool fabrics are dyed. The main purpose of this process is to remove the residual dyes, auxiliaries and impurities generated during the production process on the fabric to ensure that the fabric is clean and tidy. Washing can also adjust the shrinkage of the fabric to make it more stable and reduce the risk of deformation in subsequent processing and use.

For silk and wool fabrics, the washing process is particularly important. Because silk and wool are natural fibers, they have unique physical and chemical properties and are sensitive to washing conditions. Therefore, during the washing process, it is necessary to strictly control parameters such as water temperature, detergent type and dosage, and washing time to avoid damage to the fabric.

The impact of the washing process on the final texture of the fabric is mainly reflected in the following aspects:

Cleanliness: Washing can completely remove stains and impurities on the fabric, making the fabric cleaner and fresher.

Feel: Proper washing treatment can make the fabric feel softer and more comfortable, and improve the wearing experience.

Stability: Through washing treatment, the shrinkage of the fabric is adjusted, the stability is enhanced, and the risk of deformation in subsequent processing and use is reduced.

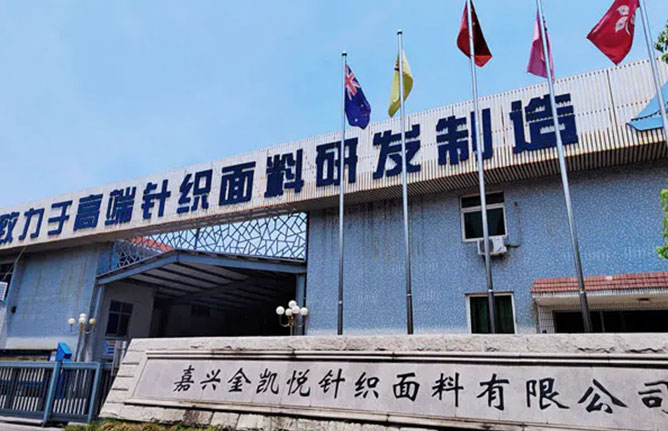

Jiaxing Jinkaiyue Knitted Fabric Co., Ltd. strictly controls and manages the washing process when producing silk and wool fabrics. The company is equipped with advanced washing equipment and technicians to ensure that each batch of fabrics can get the best washing treatment effect. The company also pays attention to the procurement and quality control of raw materials to ensure the quality and stability of fabrics from the source.

The ironing process is an important finishing link for silk and wool fabrics after dyeing. Through ironing, the fabric can be made smoother and crisper, and the overall appearance quality of the fabric can be improved. Ironing can also improve the feel and gloss of the fabric to a certain extent.

For silk wool fabrics, special attention should be paid to temperature control when ironing. Because silk and wool are heat-sensitive fibers, excessively high temperatures can easily damage the fabric, causing deformation, discoloration and other problems. Therefore, during the ironing process, it is necessary to select appropriate ironing equipment and temperature parameters to ensure that the fabric gets the best ironing effect.

The impact of the ironing process on the final texture of the fabric is mainly reflected in the following aspects:

Flatness: Ironing can make the fabric smoother and crisper, and improve the overall appearance quality of the fabric.

Glossiness: Proper ironing can improve the glossiness of the fabric, making it brighter and more textured.

Feel: Ironing can also improve the feel of the fabric to a certain extent, making it softer and more comfortable.

Jiaxing Jinkaiyue Knitted Fabric Co., Ltd. also strictly controls and manages the ironing process. The company is equipped with advanced ironing equipment and professional technicians to ensure that each batch of fabrics can get the best ironing effect. The company also pays attention to temperature control and time management during the ironing process to avoid unnecessary damage to the fabric.

The finishing process is the last processing link after silk and wool fabrics are dyed. The main purpose of this process is to further modify and beautify the fabric and improve the overall quality and added value of the fabric. The finishing process includes a variety of treatment methods, such as softening, anti-wrinkle, waterproofing, etc.

For silk wool fabrics, the choice of finishing process needs to be determined according to the specific use of the fabric and customer needs. For example, fabrics used to make high-end clothing such as suits and coats need to be softened and anti-wrinkle treated to improve the wearing comfort and stiffness of the fabrics; fabrics used to make outdoor sportswear need to be waterproofed to enhance the waterproof performance of the fabrics.

The impact of the finishing process on the final texture of the fabric is mainly reflected in the following aspects:

Functionality: Through the finishing process, the fabric can have more functional characteristics, such as waterproof, anti-wrinkle, softness, etc.

Aesthetics: The finishing process can also further modify and beautify the fabric to enhance the overall aesthetics and added value of the fabric.

Durability: Appropriate finishing can enhance the durability of the fabric and extend the service life of the fabric.

Jiaxing Jinkaiyue Knitted Fabric Co., Ltd. has also conducted in-depth research and exploration on the finishing process. The company has a professional R&D team and technicians dedicated to developing new finishing technologies and products to meet the needs of different customers. The company also pays attention to communication and cooperation with customers, and adjusts and optimizes products according to the specific needs and feedback of customers.

As the main post-processing processes for silk wool fabrics after dyeing, washing, ironing and finishing processes have a profound impact on the final texture of the fabrics. These processes not only affect the appearance, color and overall quality of the fabrics, but also determine the wearing comfort and service life of the fabrics to a certain extent.

The washing process ensures the cleanliness and stability of the fabrics; the ironing process improves the flatness and glossiness of the fabrics; the finishing process gives the fabrics more functional characteristics and aesthetics. These processes cooperate with each other and work together to enable silk and wool fabrics to show extraordinary high-end texture when they are finally presented.

The post-processing processes after silk and wool fabrics are dyed have a profound impact on the final texture of the fabrics. These processes not only improve the overall quality and added value of the fabrics, but also determine the wearing comfort and service life of the fabrics to a certain extent. Therefore, the quality and effect of these processes need to be strictly controlled and managed during the production process to ensure the quality and quality of the final product.

Tá ár gcumas déantúsaíochta comhoiriúnach le cumais láidre T&F, rud a chuireann ar ár gcumas líon mór tionscadal a sheachadadh le caighdeán níos fearr agus le hamlínte ama níos giorra.

Cumais Déantúsaíochta

Feabhsaíonn cumais láidre déantúsaíochta do chumas iomaíochta

-

Chun caighdeán níos fearr a chinntiú, tá infheistíocht déanta ag Jin Hyatt i meaisíní ceannródaíocha ón Iodáil, ón nGearmáin, ón Eilvéis, ón tSeapáin agus ó Taiwan.

-

Déileálann an comhlacht go príomha le réimse ábhar, lena n-áirítear síoda mulberry, cadás amóinia leachtach, olann, caismír, fabraicí spóirt lasmuigh agus meascáin snáithíní éagsúla.

-

Bainistíonn an chuideachta stóráil amhábhar agus táirgí críochnaithe go héifeachtach, comhtháthaíonn sí an próiseas táirgthe ar fad agus feabhsaíonn sí éifeachtúlacht fhoriomlán.

-

Díríonn an comhlacht ar an margadh ard-deireadh le fabraicí cniotáilte ardchaighdeáin agus tugtar 20% dá lucht saothair do thaighde agus forbairt chun luach agus iomaíochas táirgí a fheabhsú.

中文简体

中文简体