Réamhrá: Bunús Tee Foirfe Is stáplacha wardrobe domhanda é an t-léine humble, ach ní cruthaítear gach tees comhionann. Tá an difríocht mhór idir meán-léine agus léine a mhothaíonn cosúil le dara...

Léigh tuilleadhFabraicí olann cniotáilte saincheaptha agus cashmere atá in-nite sa mheaisín

Tá Cashmere díorthaithe ón olann fhíneáil ag fréamh na gruaige garbh ar chraiceann seachtrach na ngabhar. Níl an t -aschur bliantúil ach thart ar 100 go 200 gram. Tá sé thar a bheith luachmhar agus tugtar "ór bog" air. Tá a mhíne snáithín aonfhoirmeach, mothaíonn sé thar a bheith bog, agus tá an taithí ag caitheamh thar barr, ag soláthar an chompord deiridh. Tá feidhmíocht coinneála na dteas i bhfad níos mó ná an olann. Féadann sé ciseal aeir a insíonn teas a chruthú, an t-aer fuar a leithlisiú go héifeachtach, agus teocht an choirp a choinneáil, ag cinntiú go bhfuil sé fós te sa gheimhreadh. Tá fabraic Cashmere éadrom agus ní bheidh ualach air, rud a fhágfaidh go mbeidh sé áisiúil do chaitheamh agus taisteal laethúil. Tá ionsú taise maith agus airíonna taise taise ag Cashmere, ar féidir leo taise coirp an duine a rialáil, an craiceann a choinneáil tirim, agus gan a bheith stuama fiú má chaitear é ar feadh i bhfad. Is rogha mhaith é Cashmere le haghaidh fabraicí éadaí ardleibhéil mar gheall ar a neamhchoitianta, a choinneáil teas, éadrom, agus an t-inmharthanacht mhaith, rud a thugann compord agus cosaint neamhghnách don duine féin. I measc ábhar teicstíle, tá seasamh tábhachtach ag Cashmere lena bhuntáistí uathúla. $ $

-

-

Mar innealtóireacht teicstíle agus éadaí soláthraí réitigh, speisialtóireacht ár gcuideachta i bhfoinsiú, a mheas, agus a sholáthar ábhair fabraice chun cinn do mhonaróirí éadaigh, brandaí, agus fo...

Léigh tuilleadh -

1. Cén fáth go bhfuil Cumasc Cotton Silk ar an Rogha Cliste le haghaidh Léinte Saincheaptha Ard-Deireadh? Is minic a bhíonn aincheist clasaiceach mar thoradh ar shaothrú na fabraice léine foirfe...

Léigh tuilleadh -

Iniúchadh a dhéanamh ar na Buntáistí a bhaineann le Fabraic Cniotála Jacquard Mercerized le haghaidh Craiceann Íogaire Is minic a bhíonn deacrachtaí ag daoine aonair a bhfuil craiceann íogair or...

Léigh tuilleadh -

Díphacáil Sármhaitheas Snáithín Cadáis Supima An Buntáiste Stáplacha Breise-Fada: Marthanacht agus Bog Tá bunús na teicstíle eisceachtúil seo in úsáid a bhaint as cadás Supima, éagsúlach...

Léigh tuilleadh

What spinning and weaving technologies are used to produce knitted wool/cashmere machine washable fabrics? How do these technologies ensure the stability and durability of the fabrics?

Spinning technology

1. Compact spinning technology

Compact spinning technology is one of the important breakthroughs in modern spinning technology. It significantly reduces the hairiness of the yarn and improves the strength and uniformity of the yarn by adding a cohesion zone during the spinning process, so that the fibers are better arranged and cohesive before twisting. In the spinning process of wool and cashmere, the application of compact spinning technology can effectively reduce the shedding and pilling of fibers, making the fabric more durable and easy to care for.

2. Vortex spinning technology

Vortex spinning technology is an efficient spinning method, especially suitable for spinning short fibers. It uses high-speed rotating airflow to entrain the fibers into the vortex, and twists and coheses the fibers under the action of the vortex. Vortex spinning yarn has the characteristics of compact structure, high strength and less hairiness. In the spinning of wool and cashmere, the application of vortex spinning technology can make the yarn more delicate and uniform, while improving the anti-pilling and wear resistance of the fabric.

3. Siro Spinning Technology

Siro spinning is a two-ply twisting spinning method that feeds two rovings into a spinning machine in parallel and gradually merges them into one yarn during the twisting process. This method can significantly improve the yarn uniformity and strength while reducing hairiness. In the spinning process of wool and cashmere, the application of Siro Spinning technology can make the yarn softer and smoother, and improve the comfort and durability of the fabric.

Weaving Technology

1. Circular Knitting Machine Technology

The advanced circular knitting machines used by Jinkaiyue can efficiently and flexibly produce a variety of soft cashmere knitted fabrics. These knitting machines are equipped with sophisticated electronic control systems and a variety of knitting elements, which can realize the production of a variety of knitting types such as flat needles, rib needles, jacquard needles, etc. In the weaving process of wool and cashmere machine washable fabrics, the circular knitting machine can ensure the uniform distribution of yarns and the stability of the knitting structure, thereby improving the overall quality and durability of the fabric.

2. High-density weaving technology

High-density weaving technology is to increase the density of the warp and weft yarns of the fabric to improve the tightness and wear resistance of the fabric. In the weaving process of wool and cashmere fabrics, the use of high-density weaving technology can make the fabric thicker and tighter, effectively preventing the shedding and pilling of fibers. High-density weaving technology can also improve the wrinkle resistance and shape retention of fabrics, so that the fabrics maintain a good shape during washing and wearing.

3. Special knitting structure technology

In order to meet the special needs of wool and cashmere machine washable fabrics, Jinkaiyue also uses a variety of special knitting structure technologies. For example, by adjusting the parameters of the knitting machine and the configuration of the knitting elements, fabrics with special textures and patterns can be produced. These special knitting structures can not only improve the visual effect and fashion sense of the fabric, but also improve its stability and durability by changing the fiber arrangement inside the fabric.

Technical details to ensure fabric stability and durability

1. Fiber pretreatment

Before spinning and weaving, pretreatment of wool and cashmere fibers is a key step to improve fabric stability and durability. The pretreatment process includes cleaning, degreasing, softening and other processes, which are aimed at removing impurities and grease on the fiber surface and improving the wettability and spinnability of the fiber. Softening treatment can also reduce the damage and breakage of fibers during spinning and weaving.

2. Yarn strengthening treatment

In order to improve the strength and wear resistance of wool and cashmere yarns, Jinkaiyue adopts a variety of yarn strengthening treatment methods. For example, an appropriate amount of anti-pilling fiber or elastic fiber is added to the yarn to improve the anti-pilling and elastic recovery ability of the yarn. In addition, the surface properties of the yarn can be improved by chemical treatment or physical methods to reduce friction and wear between fibers.

3. Fabric post-treatment

Fabric post-treatment is an important link to improve the stability and durability of Knitted Wool And Cashmere Machine Washable Fabrics. This includes shrinking, napping, ironing, finishing and other processes. Shrinking treatment can make the fabric softer and more delicate, while improving the warmth and wrinkle resistance of the fabric. Napping treatment can increase the fluffy feeling and warmth of the fabric. Ironing and finishing processes can eliminate the wrinkles and color differences caused by the fabric during weaving and dyeing, and improve the overall beauty and durability of the fabric.

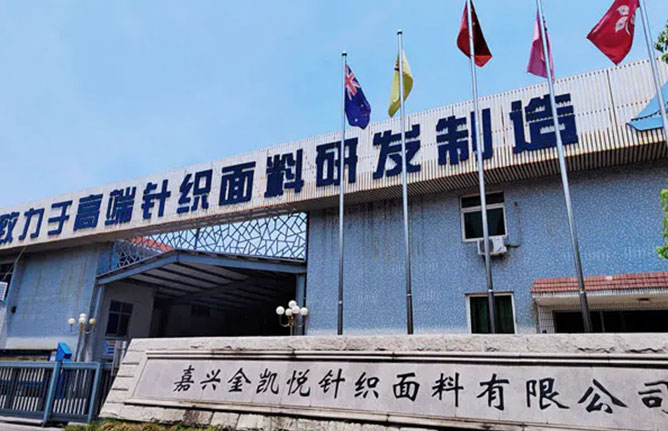

Tá ár gcumas déantúsaíochta comhoiriúnach le cumais láidre T&F, rud a chuireann ar ár gcumas líon mór tionscadal a sheachadadh le caighdeán níos fearr agus le hamlínte ama níos giorra.

Cumais Déantúsaíochta

Feabhsaíonn cumais láidre déantúsaíochta do chumas iomaíochta

-

Chun caighdeán níos fearr a chinntiú, tá infheistíocht déanta ag Jin Hyatt i meaisíní ceannródaíocha ón Iodáil, ón nGearmáin, ón Eilvéis, ón tSeapáin agus ó Taiwan.

-

Déileálann an comhlacht go príomha le réimse ábhar, lena n-áirítear síoda mulberry, cadás amóinia leachtach, olann, caismír, fabraicí spóirt lasmuigh agus meascáin snáithíní éagsúla.

-

Bainistíonn an chuideachta stóráil amhábhar agus táirgí críochnaithe go héifeachtach, comhtháthaíonn sí an próiseas táirgthe ar fad agus feabhsaíonn sí éifeachtúlacht fhoriomlán.

-

Díríonn an comhlacht ar an margadh ard-deireadh le fabraicí cniotáilte ardchaighdeáin agus tugtar 20% dá lucht saothair do thaighde agus forbairt chun luach agus iomaíochas táirgí a fheabhsú.

中文简体

中文简体